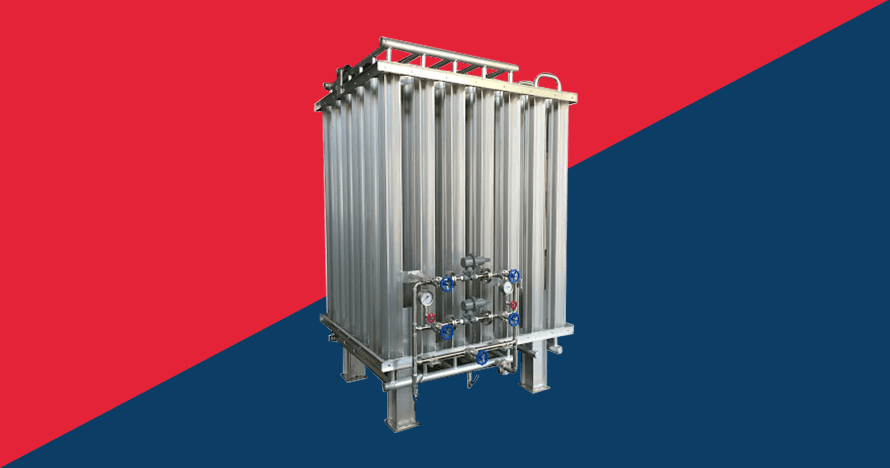

VSPV Vaporizer size varies from 50 Nm3/Hr to 50,000 Nm3/Hr with options of low-pressure and high-pressure model option.

VSPV atmospheric vaporizers are designed as per ASME Section – VIII, Division 1, and meets international codes like UBC or ASCE 7 – 10, IS code any seismic zone and wind speed up to 240 Km/Hr

VSPV vaporizers for LNG are approved for manufacturing by Govt. of India statutory agency PESO.

Randomised words which don’t look even slightly believable. If you are going passage of you need sure there anything make a type specimen book. It has survived not only five centuries.

Randomised words which don’t look even slightly believable. If you are going passage of you need sure there anything make a type specimen book. It has survived not only five centuries.